| Payment Type: | L/C,T/T |

|---|---|

| Incoterm: | FOB,CIF |

| Min. Order: | 50 Meter |

| Delivery Time: | 15 Days |

Additional Info

Productivity: 100000m

Brand: fengyisheng

Transportation: Ocean

Place of Origin: yangzhou

Certificate: ISO9001

Port: Shanghai

Product Description

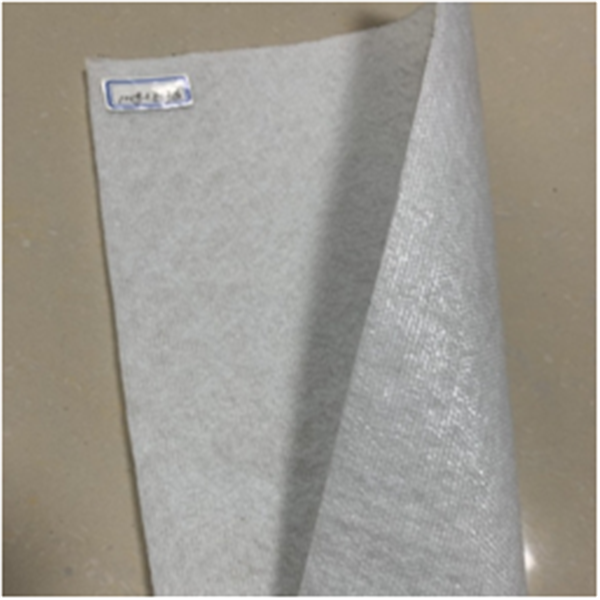

The primary back of carpet produced by our company is made up of a layer of PP woven cloth and a layer of non-woven fabric. It is used for carpet production. It is easier to back glue and the carpet has better flatness.

There is no environmental stress cracking in PP. Generally, PP is modified by adding glass fiber, metal additive or thermoplastic rubber. The MFR of PP ranged from 1 to 40. PP with low MFR has better impact resistance but lower ductility. For the same MFR material, the strength of copolymer type is higher than that of homopolymer type Due to crystallization, the shrinkage of PP is quite high, generally 1.8-2.5%. And the direction uniformity of shrinkage is much better than PE-HD and other materials. Adding 30% glass additive can reduce the shrinkage to 0.7% PP materials of homopolymer type and copolymer type have excellent moisture absorption resistance, acid-base corrosion resistance and solubility resistance. However, it has no resistance to aromatic hydrocarbon (such as benzene) solvent and chlorinated hydrocarbon (carbon tetrachloride) solvent.